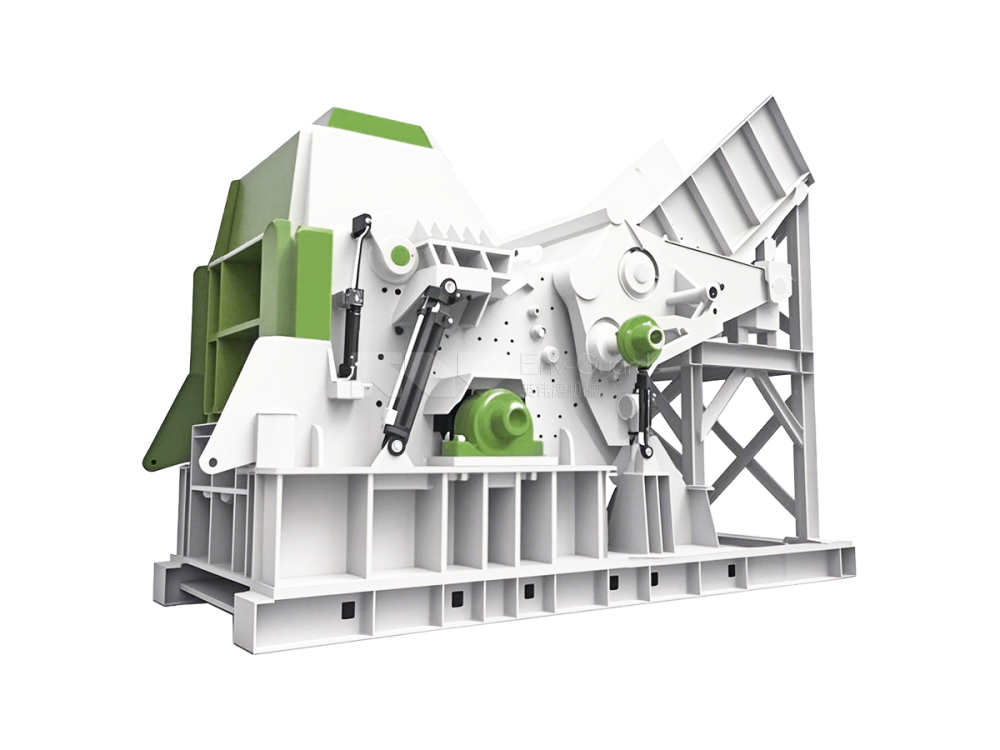

Wood Shredding Machine

Designed to process a variety of wood materials including tree branches, logs, furniture scraps, construction formwork and waste pallets

Hot Sale Wood Shredding Machine For Sale

Competitive points

Env-Guard Wood Shredding Machine Advantages

High Torque For Tough Materials

Boasts high torque output to effortlessly shear dense hardwood, thick logs, and nail-embedded wood waste without jamming, ensuring stable operation for heavy-duty tasks.

Adjustable Output Size

Allows flexible adjustment of shred size via blade spacing or screen replacement to meet diverse demands, from coarse mulch to fine biomass pellet feedstock.

Durable Blades

Made of high-hardness alloy steel with heat treatment, the blades resist wear and impact, extending service life and reducing the frequency of replacement and maintenance.

Low Noise & Dust

Equipped with sound-dampening structures and dust collection systems to minimize operational noise and dust emissions, complying with environmental and workplace standards.

Latest updates

Global Cases

Comprehensive Pallet Shredder Sent to the Philippines

Disc Shredder Test For Our Cambodian Customer

Sawdust Shredders Ready to Be Delivered to Indonesia

What our client say

Happy With Customers & Clients

We are proud to announce that our waste recycling line has been successfully exported to over 100 countries and regions across the globe. This remarkable achievement underscores our commitment to environmental sustainability and our dedication to providing innovative waste management solutions worldwide.

This wood shredding machine handles thick hardwood logs and nail-embedded pallets like a breeze—high torque never lets it jam. Saved us 30% on waste disposal costs in just 2 months!

Haile

– Ethiopia

Main parts

Key Components of EnvGuard Wood Shredding Machine

EnvGuard wood shredders rely on a robust, integrated design that ensure high torque, durability, adjustable output, and low noise/dust performance. Below is a detailed breakdown of each key part and its role:

| Component | Key Features & Functions | Technical Advantages |

|---|---|---|

| Heavy-Duty Hopper | Large, wide inlet with reinforced steel construction; optional hydraulic feeder or anti-jam sensors to handle branches, logs, pallets, and bulky wood. | Prevents material bridging; enables continuous feeding for industrial-scale operations. |

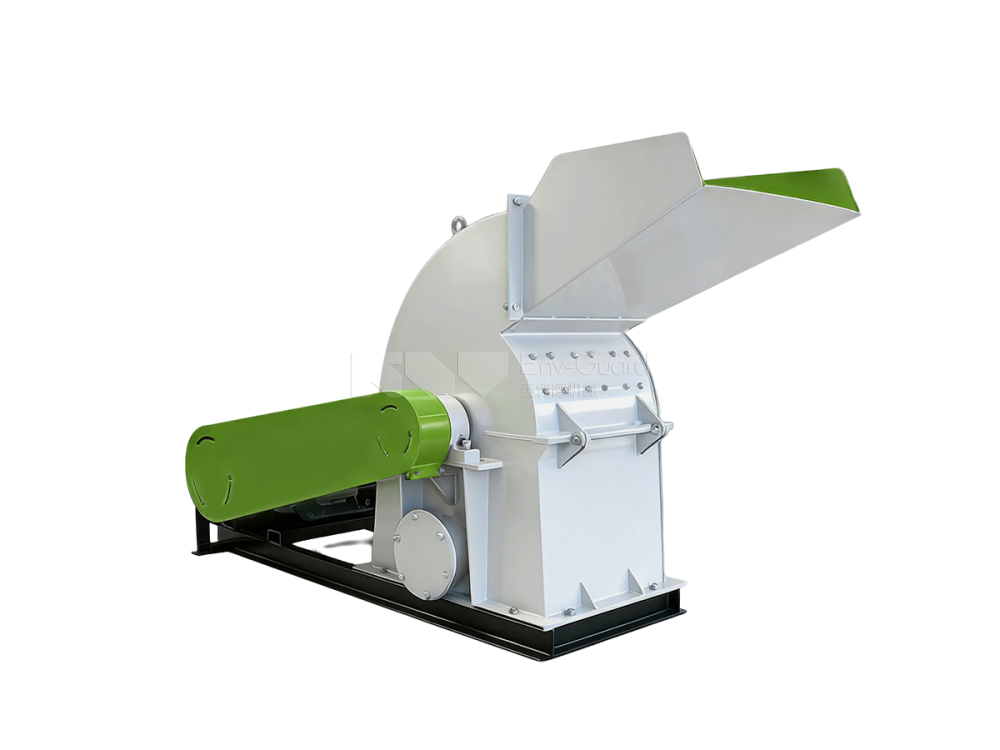

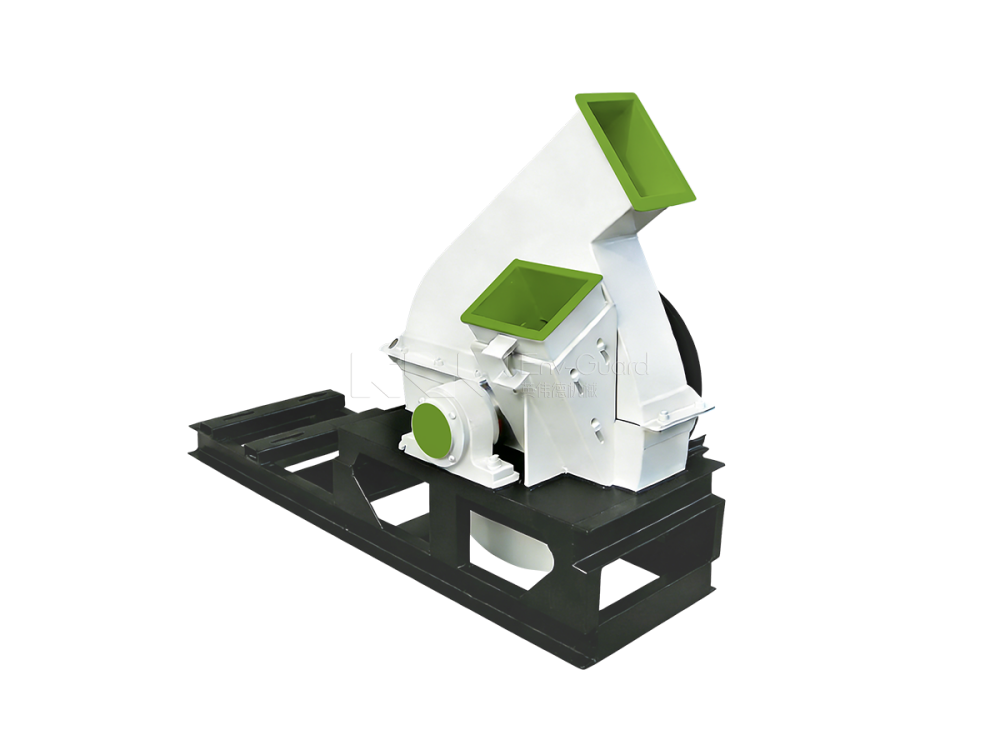

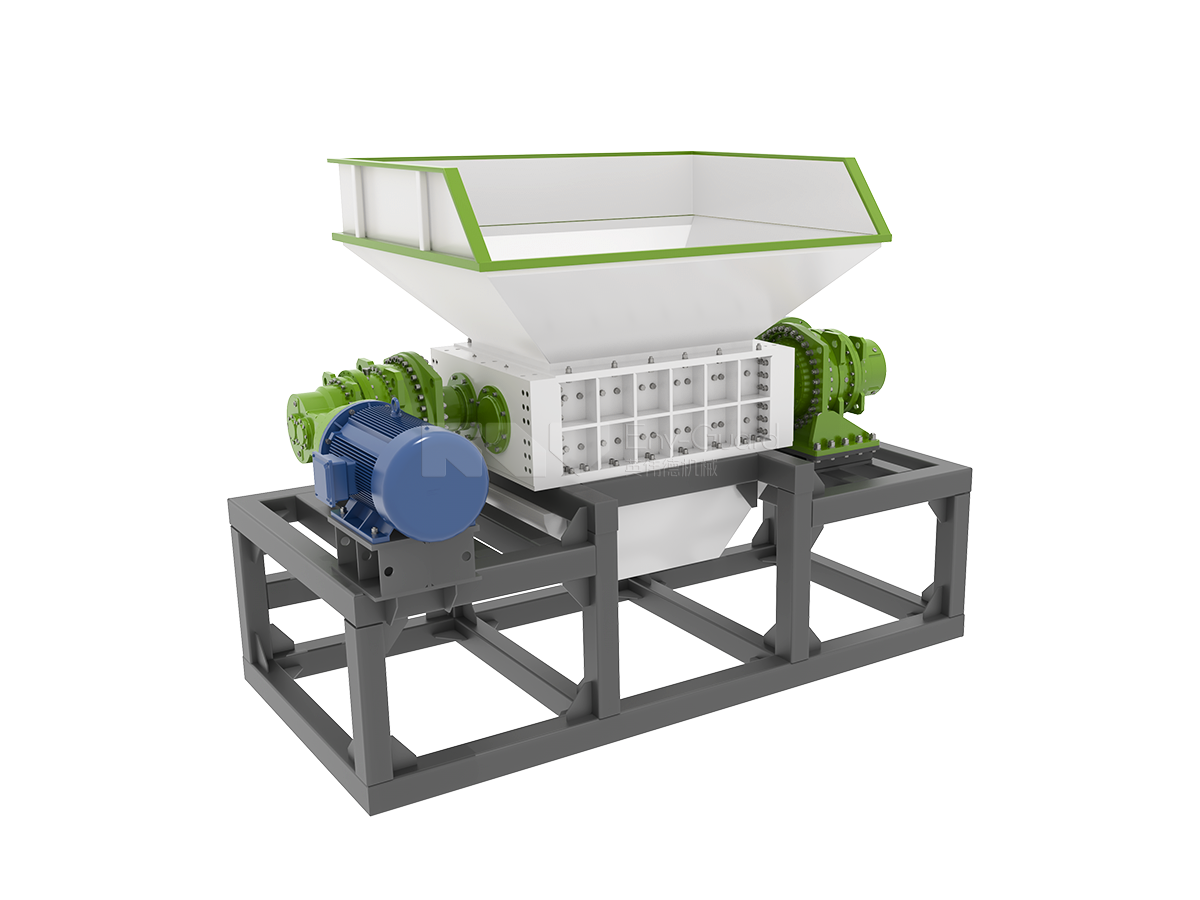

| Dual-Shaft/ Single-Shaft Shredding Chamber | Enclosed chamber housing interlocking blades (double-shaft) or helical blades (single-shaft); high-torque drive system for shearing/ tearing tough materials. | Double-shaft design handles hardwood/nail-embedded wood; single-shaft optimizes efficiency for softwood. |

| Alloy Steel Blades | SKD-11/ D2 alloy steel, heat-treated for hardness (HRC 58–62); reversible/ replaceable to extend service life. | Resists wear and impact; maintains sharpness for consistent shredding of tough materials. |

| Adjustable Blade Spacing & Screens | Interchangeable screens (5–100 mm aperture) and adjustable blade gaps to control output size from coarse mulch to fine wood chips. | Delivers uniform particle size for biomass fuel, mulch, or particleboard applications. |

| High-Torque Motor & Gearbox | Electric (15–90 kW) or diesel engine with direct/ belt drive; heavy-duty gearbox converts speed to torque (up to 10,000 Nm for double-shaft models). | Ensures stable performance for thick logs or dense wood without stalling. |

| Rotor/ Shaft Assembly | High-strength carbon steel shaft with precision machining; mounted bearings for smooth rotation and minimal friction. | Reduces vibration; extends bearing life even under heavy loads. |

| Dust & Noise Reduction System | Sound-dampening enclosure, sealed chamber, and optional cyclone dust collector to meet environmental standards (≤85 dB noise, low dust emission). | Ideal for urban/ indoor use; complies with air quality and workplace safety regulations. |

| Reinforced Steel Frame | Thick steel plate welded construction with anti-vibration pads; provides structural stability during high-torque operation. | Minimizes movement; reduces noise transmission and extends machine lifespan. |

| Discharge Conveyor/ Chute | Adjustable-angle conveyor belt or gravity chute with dust cover; transfers shredded material to storage bins or downstream equipment. | Prevents material buildup; improves workflow efficiency in automated production lines. |

Main application

Wide Usage of Wood Shredding Equipment

EnvGuard wood shredding equipment is a versatile, cost-effective tool for wood waste reduction and resource recycling, with applications spanning across multiple industries and scenarios. Its wide usage stems from its ability to convert bulky wood scraps into uniform, reusable materials (shreds, chips, or mulch). Below are its core application fields:

1. Forestry & Logging Industry

Shredders process logging residues (tree tops, branches, bark, and sawmill offcuts) that would otherwise be discarded. The shredded material can be sold as biomass fuel, used for mulching forest floors to retain soil moisture, or turned into raw material for wood-based panels. This reduces waste disposal costs and creates additional revenue streams for forestry businesses.

2. Landscaping & Gardening Services

Tree trimming and garden maintenance generate large volumes of branches, shrubs, and stumps. Mobile wood shredders allow on-site processing of these wastes into nutrient-rich mulch, which is directly applied to flower beds, lawns, and tree bases to suppress weeds, regulate soil temperature, and improve soil fertility. Landscaping companies also sell excess mulch to local garden centers for extra profit.

3. Wood Recycling & Waste Management

Recycling facilities can use heavy-duty double-shaft shredders to handle mixed wood waste, including discarded pallets, furniture scraps, construction formwork, and plywood (even those with nails or metal fasteners). Shredded wood is then sorted, processed further, and supplied to particleboard/MDF factories, biomass power plants, or animal bedding manufacturers—closing the loop for wood resource recycling.

4. Biomass Energy Production

Biomass power plants, heating systems, and pellet mills rely on wood shredders to produce consistent, high-density wood chips/shreds. These materials serve as clean, renewable feedstock for biomass combustion, replacing fossil fuels like coal and reducing carbon emissions. Small-scale shredders are also used by farms and rural households to process wood waste into fuel for heating.

5. Construction & Demolition (C&D) Sites

Demolition projects generate tons of wood waste (old wooden beams, flooring, and wall panels). Mobile wood shredders process this waste on-site, reducing its volume by up to 70% and cutting down on costly landfill transportation trips. The shredded material can be reused as fill material on-site or sold to recycling facilities.

6. Furniture & Woodworking Factories

Furniture, cabinet, and flooring factories produce massive amounts of wood offcuts, sawdust, and defective products. Shredders turn these wastes into raw material for particleboard, fiberboard, or wood-plastic composites (WPCs), minimizing production waste and lowering raw material procurement costs.

7. Agriculture & Organic Farming

Organic farms can use wood shredders to process pruned orchard branches, crop stalks, and wood waste into compost or mulch. The mulch helps improve soil structure, retain moisture, and reduce the need for chemical fertilizers. Shredded wood is also used as bedding for livestock (e.g., chickens, cows) due to its absorbency and low cost.

8. Municipal Green Waste Management

Cities and towns can deploy wood shredders to handle green waste collected from parks, streets, and residential areas (e.g., fallen leaves, tree branches, and garden trimmings). The shredded material is converted into municipal compost, which is distributed to residents or used for urban greening projects, promoting sustainable waste management.

Choosing guide

How to Choose the Right Wood Shredding Equipment?

Choosing the right wood shredder depends on 4 core factors: your processing materials, required output size, production scale, and application scenarios. Here is a step-by-step guide to make an informed decision:

1. Identify Your Raw Materials

The type and condition of wood waste determine the machine’s core configuration:

- Softwood branches/logs (pine, fir): A single-shaft shredder with standard blades is sufficient; it offers high efficiency at a lower cost.

- Hardwood, thick logs, or wood with nails (pallets, construction formwork): Opt for a double-shaft shredder—its high torque and robust shear mechanism prevent jamming and blade damage.

- Large-volume bulky wood (whole tree trunks): Choose a machine with a wide feed hopper or conveyor feeding system for continuous operation.

If you are dealing with bulky, hollow waste like pallets, crates, or furniture that often contains contaminants like nails and screws, a Double Shaft Shredder is usually the best choice. Its low-speed, high-torque shearing action grabs onto bulky items easily and cuts through metal contaminants without sustaining significant blade damage.

Conversely, if your material consists of dense, solid wood blocks, hardwood logs, or heavy manufacturing scraps, a Single Shaft Shredder is more appropriate. These machines typically feature a hydraulic ram (pusher) that forces the resistant material against a high-speed rotor, providing the aggressive cutting force needed for dense wood.

2. Determine Required Output Size & Quality

Match the shredder’s adjustability to your end product needs:

Coarse output (50–100 mm, for mulch/compost): Shredders with adjustable blade spacing work well; no additional screen is needed.

Medium output (10–50 mm, for biomass fuel, particleboard): Select a model with interchangeable screens to control particle size uniformly.

Fine output (<10 mm, for wood powder, paper pulp): Combine a shredder with a secondary grinding machine, as a single shredder cannot achieve ultra-fine results.

3. Match Capacity to Production Scale

Calculate your daily/ hourly processing volume to avoid overbuying or underperforming:

- Small-scale (<500 kg/h, home gardens, small farms): A compact, mobile single-shaft shredder (powered by 5–22 kW electric/diesel engine) is ideal.

- Medium-scale (500–2000 kg/h, landscaping, furniture factory offcuts): A stationary single-shaft or small double-shaft shredder with a conveyor is suitable.

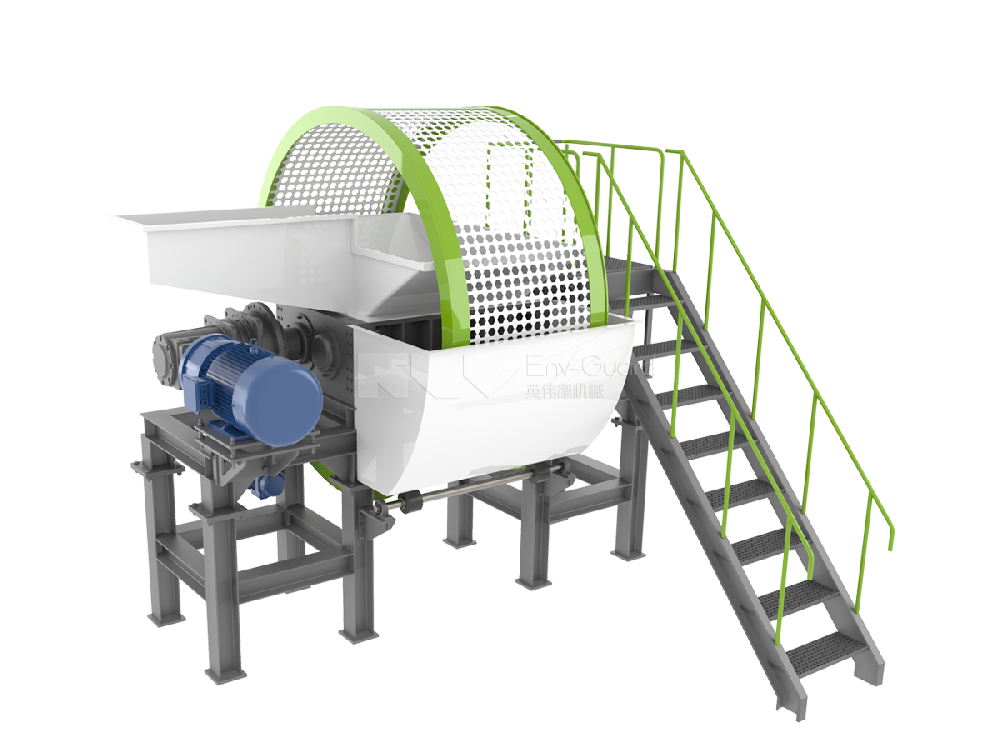

- Large-scale (>2000 kg/h, recycling plants, biomass energy projects): Invest in a heavy-duty double-shaft shredder with 55+ kW power and automated feeding/discharging systems.

4. Consider Mobility & Installation Conditions

Pick the machine type based on your work location:

- On-site processing (forestry, tree service, construction sites): Choose a mobile wood shredder with a trailer chassis—tow it directly to job sites, no fixed installation required.

- Fixed-site processing (factories, recycling yards): A stationary shredder is more cost-effective, with higher stability and easier integration into production lines.

- Space constraints: Select a compact vertical shredder instead of a horizontal one to save floor area.

5. Check Key Additional Features

- Blade durability: Prioritize blades made of high-hardness alloy steel for longer service life and lower replacement costs.

- Noise & dust control: For urban or indoor use, choose models with sound-dampening enclosures and dust collection systems to meet environmental standards.

6. Verify Budget & Cost-Effectiveness

- Single-shaft shredders are cheaper (suitable for small/medium softwood tasks).

- Double-shaft shredders have higher upfront costs but lower long-term maintenance costs for heavy-duty work.

- Mobile models cost more than stationary ones but save on transportation fees for on-site operations.

Work flow

How Does A Wood Shredder Work?

A wood shredder works by mechanically shearing, tearing, or crushing wood materials into smaller, uniform pieces through a combination of a power-driven system, cutting components, and material handling structures.

The core process can be broken down into 5 key steps, with slight variations between single-shaft and double-shaft models:

1. Material Feeding

Wood waste (branches, logs, pallets, etc.) is fed into the machine via a manual hopper, automated conveyor belt, or hydraulic feeder. EnvGuard models have anti-jam feeding mechanisms to prevent oversized materials from blocking the inlet.

2. Power Transmission

An electric motor or diesel engine drives the shredding chamber’s shafts via a belt, gearbox, or direct drive. The system converts high-speed rotation into high torque—critical for handling tough materials like hardwood or nail-embedded pallets.

3. Core Shredding Process

This is the key stage, differing by machine type:

Single-shaft shredders: A rotating shaft with sharp, helical blades grabs the wood and pulls it against stationary counter-blades. The wood is sheared into small shreds as it moves through the gap between moving and fixed blades.

Double-shaft shredders: Two parallel shafts with interlocking blades rotate in opposite directions. They clamp the wood tightly and tear it apart through shear and compression forces—ideal for thick, dense, or irregularly shaped materials.

4. Size Classification (Optional)

For machines with built-in screens, shredded wood pieces pass through a perforated screen at the bottom of the chamber. Only particles smaller than the screen’s aperture exit the machine; larger pieces are recirculated back into the shredding zone for further processing. This ensures uniform output size.

5. Material Discharge

The final small shreds are expelled from the machine via gravity (falling out the bottom), a discharge conveyor belt, or a blower system. Conveyor or blower discharge is preferred for large-scale operations to transfer shredded material directly to storage bins or downstream equipment.

Related products

Env-Guard Waste Recycling Machine For Sale

To complete your recycling suite, we also provide a variety of supplementary tools designed to optimize your recycling process and enhance efficiency.