Waste Tyre Recycling Plant

Output: 1-20mm rubber block, 10-120 mesh rubber powder

Hot Sale Tyre Recycling Plant For Sale

High efficient choice

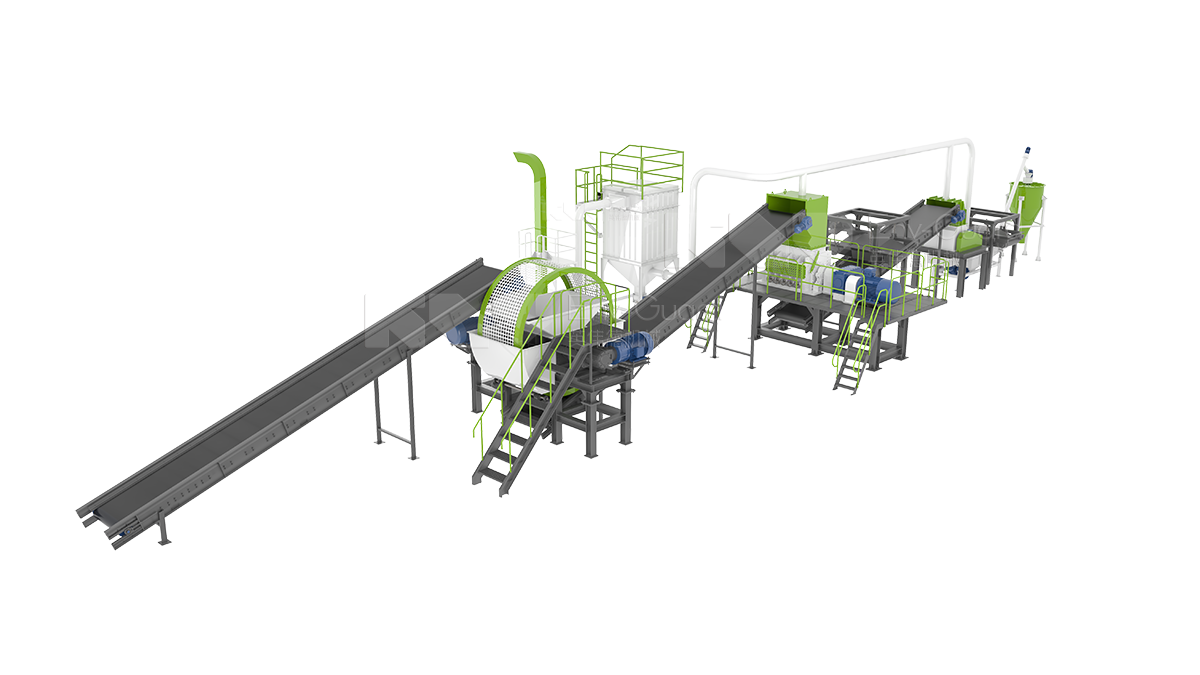

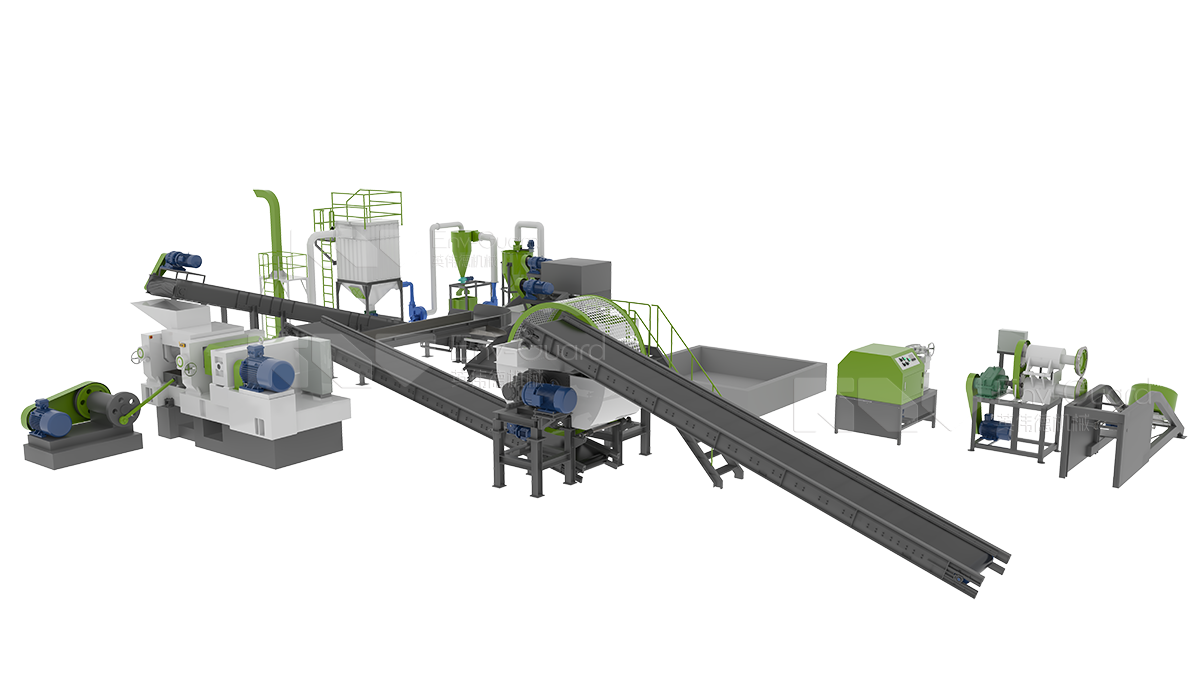

Full Automatic Tyre Recycling Plant For Sale

Utilizing cutting-edge automation technology, Env-Guard’s full automatic waste tyre recycling plant efficiently processes discarded tires into various high-quality, marketable materials.

The plant’s sophisticated system seamlessly carries out shredding, steel and fiber separation, granulation, and fine grinding. As a result, it produces crumb rubber, rubber powder, and other commodities.

Input: bicycle tire, motorcycle tire, tricycle tire, car tire, truck tire and various waste rubber products.

Output: rubber block, bead wire, small/large rubber particles, rubber powder.

Serve for wide ranges

Automatic Rubber Recycling Plant Application

Tyre Block

Env-Guard’s advanced automatic waste tire cutting production line efficiently transforms waste tires into 300-500mm rubber blocks, perfectly tailored for use in civil engineering projects and soundproofing applications.

Tyre Pellet

Our tyre pellet line expertly converts waste tyres into 1-3mm, 3-5mm and 15-20mm rubber particles, ideal for crafting top-notch sports fields, safe playground surfaces, as well as for creating resilient landscaping materials and shock-absorbent mats.

Tyre Powder

Our precision grinding line meticulously processes waste tires into 5-120 mesh rubber powder, yielding a fine, consistently granulated product that is optimal for use in manufacturing automotive components, sealants, and various coatings.

For various business scale

Full Automatic Line Specification

| Model | ENVT1000 | ENVT1200 | ENVT1500 | ENVT1900 | ENVT2600 |

| Motor Power | 30*2 Kw | 75*2 Kw | 90*2 Kw | 110*2 Kw | 160*2 Kw |

| Capacity | 1-1.5 T/H | 2-3 T/H | 4-5 T/H | 6-8 T/H | 8-12 T/H |

| Blade Quantity | 26 | 30 | 38 | 38 | 40 |

| Blade Diameter | Φ360 mm | Φ372 mm | Φ530 mm | Φ560 mm | Φ720 mm |

| Output Size | 3-8 cm | 3-8 cm | 3-8 cm | 3-8 cm | 3-8 cm |

| Input Opening Size | 1200*1000 mm | 1400*1000 mm | 2000*2000 mm | 2300*2000 mm | 2425*1400 mm |

| Dimension L/W/H | 3500*2200*3500 mm | 4600*2300*3500 mm | 5100*2400*3500 mm | 6500*2500*3500 mm | 8200*4000*3500 mm |

| Weight | 8.5 T | 13 T | 15 T | 17.5 T | 32 T |

Work flow

Full Automatic Line Work Principle

A full automatic waste tyre recycling plant is an industrial facility that transforms end-of-life tires into valuable commodities through a series of automated processes.

- These plants begin by collecting and shredding used tires into smaller pieces.

- Subsequent stages involve the removal of steel and fibers, utilizing magnetic separation and screening technologies.

- The rubber fragments are then granulated and ground into fine powders, sorted by size for various applications.

Advanced machinery within the plant ensures minimal human intervention, enhancing efficiency and safety while maintaining consistent product quality. The end products, such as crumb rubber, rubber mulch, and rubber powder, are utilized in creating new rubber products, playground surfaces, and as additives in asphalt. The recovered steel and fibers can be repurposed or recycled, further contributing to the circular economy.

These plants not only mitigate the environmental impact of tire waste but also turn a disposal challenge into an opportunity for resource recovery. The automatic nature of the plant ensures high throughput, cost-effectiveness, and adaptability to meet growing recycling demands.

Budget choice

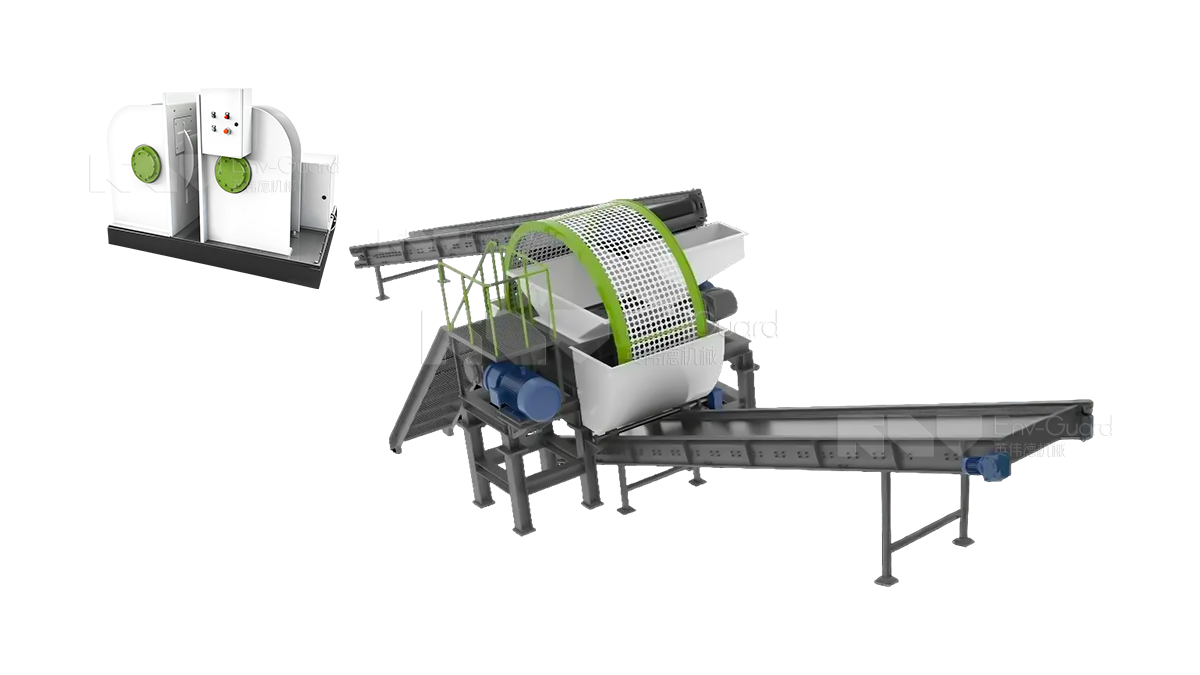

Semi Automatic Tyre Cutting System For Sale

Our semi-automatic tyre recycling plant is a robust solution designed to bridge the gap between manual processing and full automation. With a capacity to handle a significant volume of waste tyres, this plant utilizes a combination of manual oversight and mechanized operations to ensure efficiency and cost-effectiveness.

This line is composed of 4 key machines, include tire ring cutter, tire strip cutter, tire block cutter, steel wire extruder, each designed to perform a specific task in the tire recycling sequence.

Input: bicycle tire, motorcycle tire, tricycle tire, car tire, truck tire and various waste rubber tyres.

Output: 300-500mm rubber block.

For various business scale

Semi Automatic Line Specification

| Tire Ring Cutter | |

| Model | ENVQQ 1000 |

| Power | 3kw |

| Capacity | 30-40 tires/hour |

| Voltage | 380V,50HZ (Customer can specify voltage) |

| Weight | 300kg |

| Overall Dimensions | 1650×1050×1500mm |

| Tire Strip Cutter | |

| Model | ENVQT1000 |

| Power | 5.5kw |

| Capacity | 1t/h |

| Voltage | 380V,50HZ (Customer can specify voltage) |

| Weight | 700kg |

| Overall Dimensions | 1300×800×1500mm |

| Tire Block Cutter | |

| Model | ENVQK1000 |

| Power | 15kw |

| Capacity | 1t/h |

| Weight | 650kg |

| Overall Dimensions | 1080×850×1250mm |

| Steel Wire Extruder | |

| Model | ENVJS1000 |

| Capacity | 100 pcs/hour |

| Motor Speed | 1440 r/min |

| Power | 18.5kW |

| Weight | 1400kg |

| Overall Dimensions | 1600*1420*1200 mm |

Working flow

Semi Automatic Line Work Principle

The Env-Guard semi-automatic tire recycling line is an integrated system designed to streamline the initial stages of tire recycling with precision and efficiency. This line is specifically tailored for the deconstruction and preparation of waste tires for further processing and recycling. Here’s a breakdown of the core components included in the Env-Guard line:

1. Tire Ring Cutter: This is the first step in the tire recycling process, where the ring cutter removes the bead wire from the tire, creating a bead-free tire that’s easier to process further. This step is crucial for protecting the machinery in the subsequent stages from potential damage caused by the tough steel wires.

2. Tire Strip Cutter: Once the bead wire is removed, the tire strip cutter takes over, slicing the tire into long strips. This facilitates easier handling and prepares the material for the next size reduction step. The strips are uniform, making them ideal for consistent processing.

3. Tire Block Cutter: The tire strips are then fed into the tire block cutter, which dices them into smaller blocks. These blocks are more manageable for the upcoming shredding process, ensuring that the material can be processed with greater uniformity and efficiency.

4. Steel Wire Extruder: After the tires have been cut into blocks, any remaining steel wire needs to be extracted. The steel wire extruder is designed to remove this wire effectively, leaving behind clean rubber blocks. The extracted steel wire can then be recycled separately, adding value to the recycling process.

The Env-Guard line is engineered to be user-friendly, requiring minimal technical expertise to operate while ensuring safety. Each component is designed to work in harmony with the next, creating a streamlined process that saves time and labor. By focusing on the initial preparation of the tires, the Env-Guard line sets the stage for further refinement and recycling into various products, making it an essential part for small business projects.

Competitive points

Env-Guard Recycling Machines Advantages

High Purity of End Products

Env-Guard might produce rubber crumb, steel, and fiber of higher purity, which can be more valuable in the marketplace and suitable for a wider range of applications.

High Material Recovery Rate

Env-Guard’s plant boast a higher material recovery rate, meaning more of the tyre is recycled and less is wasted.

Customization and Flexibility

Offering a range of equipment configurations to suit your different needs, including various plant sizes and levels of automation.

Versatility

The ability to process a wide range of tyre sizes and types, from passenger car tyres to large truck and agricultural tyres, can provide a broader market appeal.

Latest updates

Global Cases

Tyre Cutting Plant Works in South Africa

Small Tyre Recycle Plant Tested for Indian Customer

Waste Tire Grinding Machine Installed in Sri Lanka

What our client say

Happy With Customers & Clients

We are proud to announce that our state-of-the-art waste recycling line has been successfully exported to over 100 countries and regions across the globe. This remarkable achievement underscores our commitment to environmental sustainability and our dedication to providing innovative waste management solutions worldwide.

From the onset, the Env-Guard team demonstrated exceptional professionalism. They provided a comprehensive analysis of our needs and delivered a customized solution that fit our specific requirements. The installation process was seamless, and their technicians ensured our staff was fully trained to operate the new system.

Edwin. Evwarhono

– Nigeria

Market analysis

Is Tyre Recycling Profitable?

Yes, a tire recycling plant can be profitable. The profitability of a tire recycling plant depends on various factors including the following:

Market Demand: Recycled rubber is used in various applications such as paving materials for roads, playground surfaces, landscaping mulch, and as a raw material for manufacturing new products like mats, shoes, and automotive parts. A strong market demand for these products can lead to a profitable recycling operation.

Feedstock Supply: A steady and affordable supply of used tires is crucial. If you have access to a large supply of waste tires at a low cost, it can significantly improve profitability.

Technology and Efficiency: The use of advanced recycling technology can improve the efficiency of the recycling process, reduce labor costs, and produce higher-quality end products, which can command higher prices.

Product Diversification: Facilities that can produce a range of products from recycled tires, such as crumb rubber, tire-derived fuel (TDF), and steel wire, can maximize revenue streams.

Regulations and Incentives: Some regions offer incentives for recycling, and strict regulations on tire disposal can drive the supply of waste tires towards recycling plants.

Operational Costs: Energy consumption, labor, maintenance, and transportation costs all affect profitability. Efficient operations can reduce these costs.

Environmental Impact: Recycling tires reduces the environmental impact of tire disposal, which can translate into economic benefits if the operation qualifies for carbon credits or other environmental incentives.

End-product Quality: High-quality recycled materials can be sold at a premium, enhancing profitability.

Scale: Larger operations can benefit from economies of scale, reducing the per-unit cost of recycling.

Local Competition: The level of local competition can affect the price you can charge for recycled materials.

To determine the exact profitability, one would need to conduct a detailed market analysis, consider the capital and operational expenses, and project the revenues based on the current and future market for recycled tire products. It’s also important to stay updated on technological advancements and regulatory changes that can impact the industry.

Byproducts

What Can Be Made From Recycled Tires?

The end products of a waste tyre recycling plant can include:

- Rubber Mulch: Used in landscaping and playground surfaces.

- Crumb Rubber: Utilized in the manufacture of asphalt, sports surfaces, and molded rubber products.

- Rubber Powder: Employed in the production of new rubber products or as a filler in plastics.

- Steel: Recycled into new steel products.

- Textile Fibers: Used as a fuel source or in low-grade applications.

Detailed process

What Is A Tyre Recycling Plant?

A waste tyre recycling plant is a comprehensive system designed to completely process end-of-life tires into various valuable products. The process typically involves several stages, each designed to maximize recovery and minimize waste. Here’s an overview of what such a plant might involve:

1. Pre-treatment

Size Reduction: Tires are cut or shredded into smaller pieces to facilitate further processing. This is usually done in two stages: primary shredding into strips or chips and secondary shredding into smaller pieces.

2. Steel and Fiber Removal

Steel Wire Separation: Magnetic separators are used to extract steel wiring from the tire shreds. This reclaimed steel can be recycled and used in various industries.

Fiber Separation: Fibers or textile materials are removed through a combination of shaking screens, air classifiers, or gravity separators.

3. Granulation and Grinding

Granulation: The rubber material is further reduced into small granules or crumbs. This is done using granulators and cracker mills.

Grinding: The granules are then ground into even finer particles, often down to the size of sand. This is done in a fine grinding mill, which can produce rubber powder in various sizes according to the desired application.

4. Purification and Classification

Screening: The rubber powder is screened to separate it into different size fractions.

Cleaning: The powder is further cleaned to remove any remaining contaminants, ensuring a high-purity end product.

5. Packaging

Packaging: The final rubber material is packaged into bags or bulk containers for transportation.

Related products

Env-Guard Waste Recycling Machine For Sale

To complete your recycling suite, we also provide a variety of supplementary tools designed to optimize your recycling process and enhance efficiency.