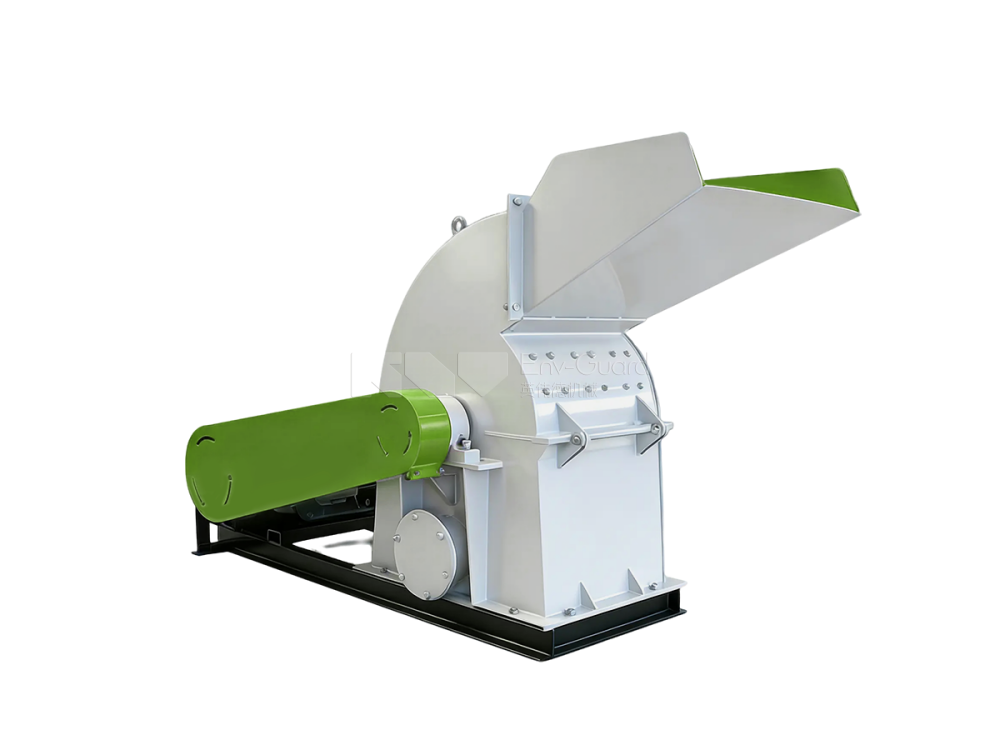

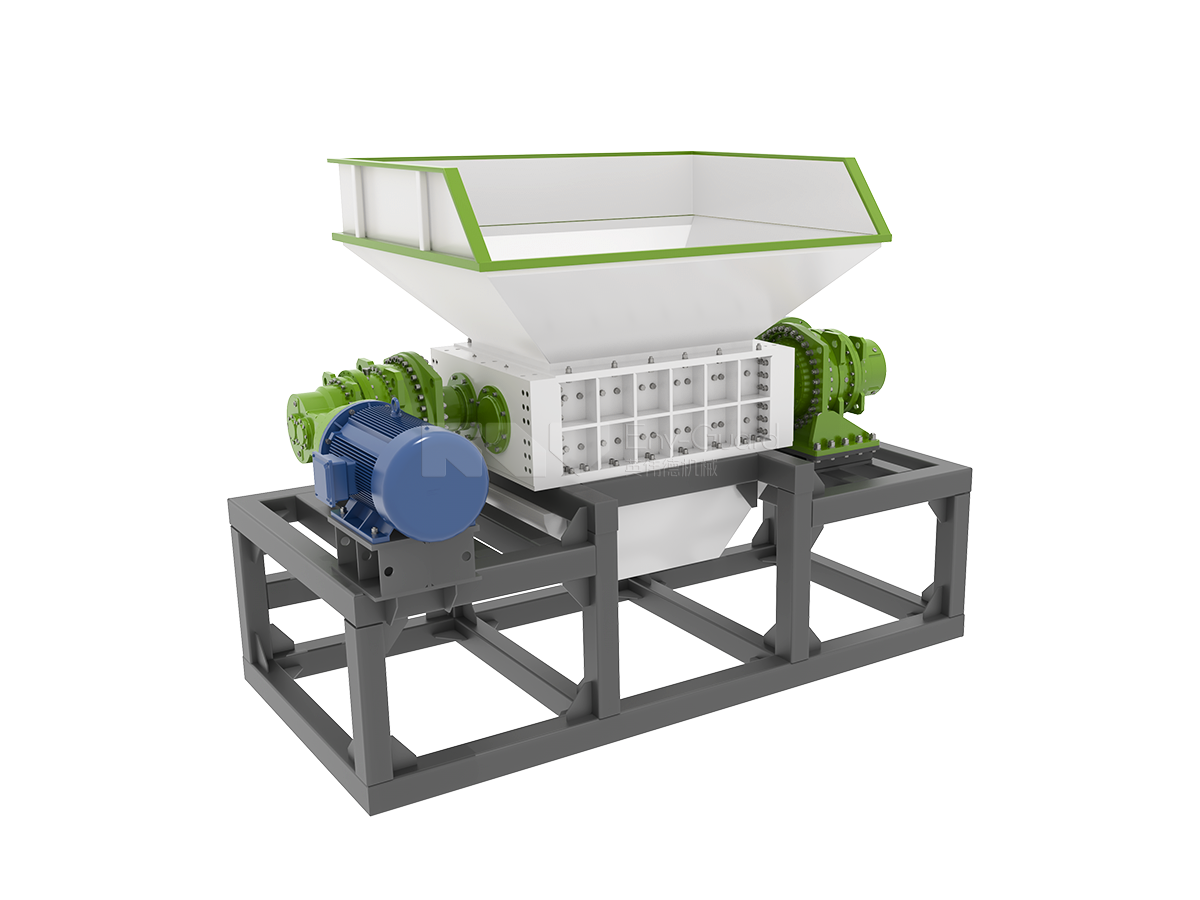

Sawdust Making Machine

1-20 t/h small to large capacity with adjustable finished chip thickness

Sawdust Making Machine For Sale

Our premium sawdust making machine is engineered to transform agricultural and forestry waste into high-quality, uniform sawdust in seconds.

Utilizing a dual-action crushing mechanism (blade cutting and high-speed hammer impact), this equipment is capable of processing raw logs, bamboo, square blocks, and wood scraps with a diameter of up to 350cm. Featuring an adjustable screen mesh, the machine allows operators to control final particle size specifically for pelletizing or briquetting lines.

Input: Logs, wood branches, wood scraps, tree stumps, bamboo, crop straws, biomass pellets, wood briquettes, animal bedding, or mushroom substrate and other wood-based or lignocellulosic materials.

Max Feed Diameter: ≤350 (mm)

Untuk pelbagai skala perniagaan

Sawdust Making Machine Specification

| Model | Capacity (t/h) | Power (kW) | Rotor Speed (r/min) | Max Feed Diameter (mm) | Max Feed Length (mm) | Finished Chip Thickness (mm) | Weight (t) | Dimensions (L×W×H, mm) |

|---|---|---|---|---|---|---|---|---|

| YWD-400 | 1.0-2.5 | 15-22 | 950-1200 | ≤120 | ≤800 | 2-5 (Adjustable) | 1.0-1.5 | 1800×900×1400 |

| YWD-500 | 2.5-4.0 | 22-37 | 850-1000 | ≤180 | ≤1000 | 2-6 (Adjustable) | 1.8-2.5 | 2200×1100×1600 |

| YWD-600 | 4.0-6.0 | 37-55 | 750-900 | ≤220 | ≤1200 | 2-6 (Adjustable) | 2.8-3.8 | 2600×1300×1800 |

| YWD-800 | 6.0-10.0 | 55-75 | 650-800 | ≤260 | ≤1500 | 3-7 (Adjustable) | 4.5-5.8 | 3200×1500×2000 |

| YWD-1000 | 10.0-15.0 | 75-90 | 550-700 | ≤300 | ≤1800 | 3-8 (Adjustable) | 6.2-7.5 | 3800×1700×2200 |

| YWD-1200 | 15.0-20.0 | 90-110 | 450-600 | ≤350 | ≤2000 | 3-8 (Adjustable) | 7.8-8.5 | 4500×1900×2400 |

Mata persaingan

Env-Guard Sawdust Making Machine Advantages

High Efficiency & High Yield

Optimized rotor with high-hardness blades delivers 1–2x higher output than traditional models. One-pass crushing eliminates secondary processing, cutting production time and labor costs.

Adjustable Particle Size

Interchangeable screens (0.5–10mm) enable flexible customization to meet diverse customer needs (e.g., fine powder for papermaking, coarse chips for biomass pellets).

Wide Material Adaptability

Handles hardwood, softwood, dry/wet wood, and even slightly contaminated materials (e.g., wood pallets with nails, with optional metal separation system).

Energy-Saving & Low Cost

Energy-efficient motor design reduces power consumption by 20%. Compact structure minimizes space usage, lowering operational overhead.

Kemas kini terkini

Kes Global

Pengisar Serpihan Kayu Siap Dihantar ke Indonesia

Sawdust Grinder Ready to Be Sent to South Africa

Sawdust Making Machine Test For Mexican Customer

Apa yang pelanggan kami katakan

Gembira Bersama Pelanggan & Pelanggan

Kami berbesar hati untuk mengumumkan bahawa barisan kitar semula sisa kami telah berjaya dieksport ke lebih 100 negara dan wilayah di seluruh dunia. Pencapaian luar biasa ini menekankan komitmen kami terhadap kelestarian alam sekitar dan dedikasi kami untuk menyediakan penyelesaian pengurusan sisa yang inovatif di seluruh dunia.

We bought the Model 600 diesel crusher to prepare raw material for our wood pellet line. The sawdust comes out uniform (mostly 3-5mm), which means we don’t have to re-screen it. It handles pine and rubber wood logs easily. Highly recommended for anyone in the biomass energy business.

Rebecca Kakonda

– Namibia

Kebolehsesuaian yang luas

Input Raw Material of Our Sawdust Making Machine

Our high-efficiency sawdust making machine is designed to process a wide range of lignocellulosic raw materials, supporting diverse production needs from small workshops to large-scale biomass lines.

Below is the detailed list of applicable input materials, along with key parameters for your reference:

Wood Waste & Offcuts

- Furniture factory scraps, construction wood templates, pallets, wooden boxes, and waste lumber.

- Hardwood, softwood, and mixed wood (no large metal impurities; optional metal separator for contaminated materials).

- Feeding size: Max diameter 5–50cm (adjustable for different models); length ≤2m (for direct feeding).

Forestry & Garden Waste

- Logs, tree branches, twigs, stumps, and deadwood.

- Garden pruning waste, shrub trimmings, and forestry residues (ideal for green waste recycling).

Bamboo & Agricultural Residues

- Bamboo poles, bamboo scraps, and bamboo shoots residues.

- Crop straws (corn stalks, wheat straw, rice straw), sugarcane bagasse, and cotton stalks (dry or slightly wet).

Specialized Materials

- Coconut shell, peanut shell, and other lignocellulosic by-products (for high-value sawdust production).

- Wood chips, shavings, and bark (for fine sawdust or biomass pellet feedstock).

Continuous & uniform

Finished Products of Our Sawdust Making Machine

Our Sawdust Making Machine processes various lignocellulosic raw materials into uniform, high-quality finished sawdust/wood chips with adjustable particle sizes, meeting the strict requirements of multiple industries. Below is a detailed breakdown of the finished products, their specifications, and core applications:

The machine’s primary output is processed wood powder/wood chips, categorized by particle size to suit different use cases:

Fine Sawdust (0.5–3mm)

- Ultra-fine, uniform powder with consistent fiber length.

- Low impurity content, high purity, and loose texture.

Medium Wood Chips (3–6mm)

- Granular wood fragments with balanced hardness and air permeability.

- Ideal for materials requiring moderate density and combustion efficiency.

Coarse Wood Chips (6–10mm)

- Larger, structured wood particles with high bulk density.

- Suitable for applications needing robust structural support or high calorific value.

Target Marketing

Broad Application of Sawdust Making Machine

Our high-efficiency sawdust making machine is a versatile industrial solution that transforms wood waste, forestry residues, and agricultural by-products into high-value sawdust/wood chips.

With its wide material adaptability and adjustable particle size, the machine serves 6 core industry sectors globally, driving circular economy and cost efficiency for businesses of all scales.

Below is its comprehensive application landscape:

1. Biomass Energy Industry

The machine’s primary high-value application is supplying raw materials for biomass energy production:

- Biomass Pellet & Briquette Production: Processes wood waste into uniform sawdust (0.5–6mm) for pellet mills, creating eco-friendly fuel for heating, power generation, and industrial boilers.

- Charcoal Making: Converts branches, logs, and coconut shells into high-quality charcoal feedstock, ideal for barbecue, industrial smelting, and activated carbon production.

- Bio-Gas & Bio-Power Plants: Provides lignocellulosic raw materials for anaerobic digestion and biomass power generation, supporting renewable energy projects worldwide.

2. Edible Fungi & Mushroom Cultivation

A critical application for agricultural and horticultural industries:

- Mushroom Substrate Manufacturing: Produces fine sawdust (0.5–3mm) as the core nutrient medium for shiitake, oyster mushroom, wood ear, and ganoderma lucidum cultivation.

- Benefit: The loose, breathable texture of our finished sawdust promotes rapid mycelium growth, increasing mushroom yield by 15–25% and improving product quality.

3. Wood Processing & Building Materials Industry

Turns factory waste into valuable raw materials for construction and furniture manufacturing:

- Wood Panel Production: Supplies consistent wood fiber for particleboard, MDF (medium-density fiberboard), OSB (oriented strand board), and plywood manufacturing.

- Furniture & Decoration Materials: Processes wood scraps into high-purity sawdust for veneer production, wood fiber composites, and decorative board manufacturing.

- Circular Economy Solution: Recycles furniture factory offcuts, construction templates, and waste pallets, reducing raw material costs and environmental waste.

4. Papermaking & Textile Industries

Supplies premium raw materials for paper and fiber-based products:

- High-Quality Papermaking: Fine sawdust (0.5–2mm) is processed into wood pulp for writing paper, tissue paper, packaging paper, and cardboard production.

- Wood Fiber Textiles: Used to manufacture eco-friendly wood fiber fabrics, non-woven materials, and composite textiles for clothing, home textiles, and industrial filtration.

5. Garden & Agricultural Waste Recycling

Supports sustainable landscaping and agricultural management:

- Garden & Landscaping: Converts tree branches, shrub trimmings, and garden waste into coarse wood chips (6–10mm) for organic mulch, soil conditioner, and compost raw materials.

- Agricultural Applications: Used as animal bedding (absorbent, odor control) for livestock farms, and as a carbon source for organic fertilizer production, improving soil fertility and moisture retention.

6. Specialized High-Value Industries

Additional niche applications that drive additional revenue streams:

- Fire Starter Manufacturing: Produces fine sawdust mixed with wax to create eco-friendly fire starters for camping, barbecues, and household use.

- Chemical & Pharmaceutical Industries: Raw material for activated carbon production (used in water purification, air filtration, and drug purification).

- Animal Bedding & Pet Products: High-purity sawdust serves as absorbent, odor-resistant bedding for horses, poultry, and small pets.

Take Care

Sawdust Making Machine Key Feeding Requirements

Moisture Content: Ideal for materials with 10–25% moisture; slightly wet materials (≤30%) are acceptable, while overly wet materials may cause clogging (optional drying system available).

Impurity Control: Free of large stones, metal nails, and hard debris; optional accessories (magnetic separator, pre-crusher) can remove impurities for extended machine life.

Feeding Method:

- Manual feeding via hopper (for small models, 0.3–1 ton/h).

- Automatic conveyor belt feeding (for medium/large models, 1–7 tons/h) for continuous, high-efficiency production.

Produk berkaitan

Mesin Kitar Semula Sisa Env-Guard Untuk Dijual

Untuk melengkapkan set kitar semula anda, kami juga menyediakan pelbagai alat tambahan yang direka untuk mengoptimumkan proses kitar semula anda dan meningkatkan kecekapan.