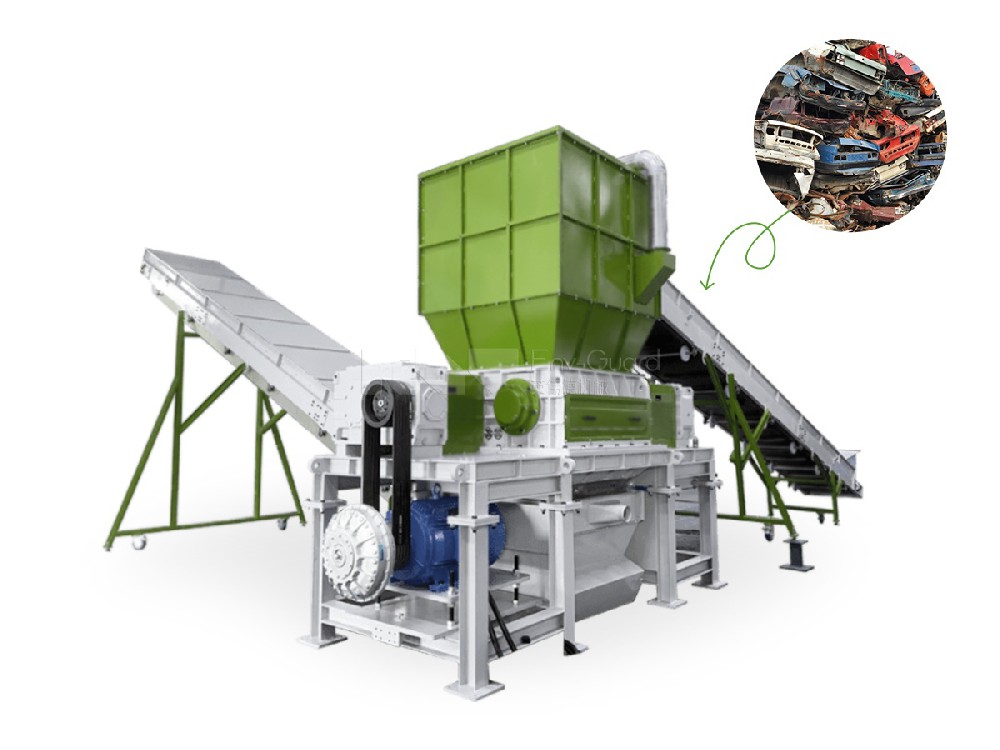

Metal Shredding Production Line

Designed to shred and sort various waste metal light and thin materials to obtain non-ferrous metals with high purity.

Cost effective choice

Scrap Metal Recycling Plant

EnvGuard is a China-based manufacturer specializing in solid waste treatment and recycling equipment.

With high metal recovery rates, Env-Guard offers turnkey metal shredding production lines tailored for ferrous/non-ferrous scrap (steel, aluminum, copper, e-waste, auto hulks, etc.).

Input: waste car bodies, tinplate, home appliances, bicycles, truck fences and similar household waste, cans, and other scrap steel which with a desncity ≤0.6, or with a thickness of ≤6mm.

Feed Size: 180-1000mm

Discharge Size: 50-100mm

Capacity: 1-5t/h

Complete plant

Metal Shredding Production Line Configuration

Waste Metal

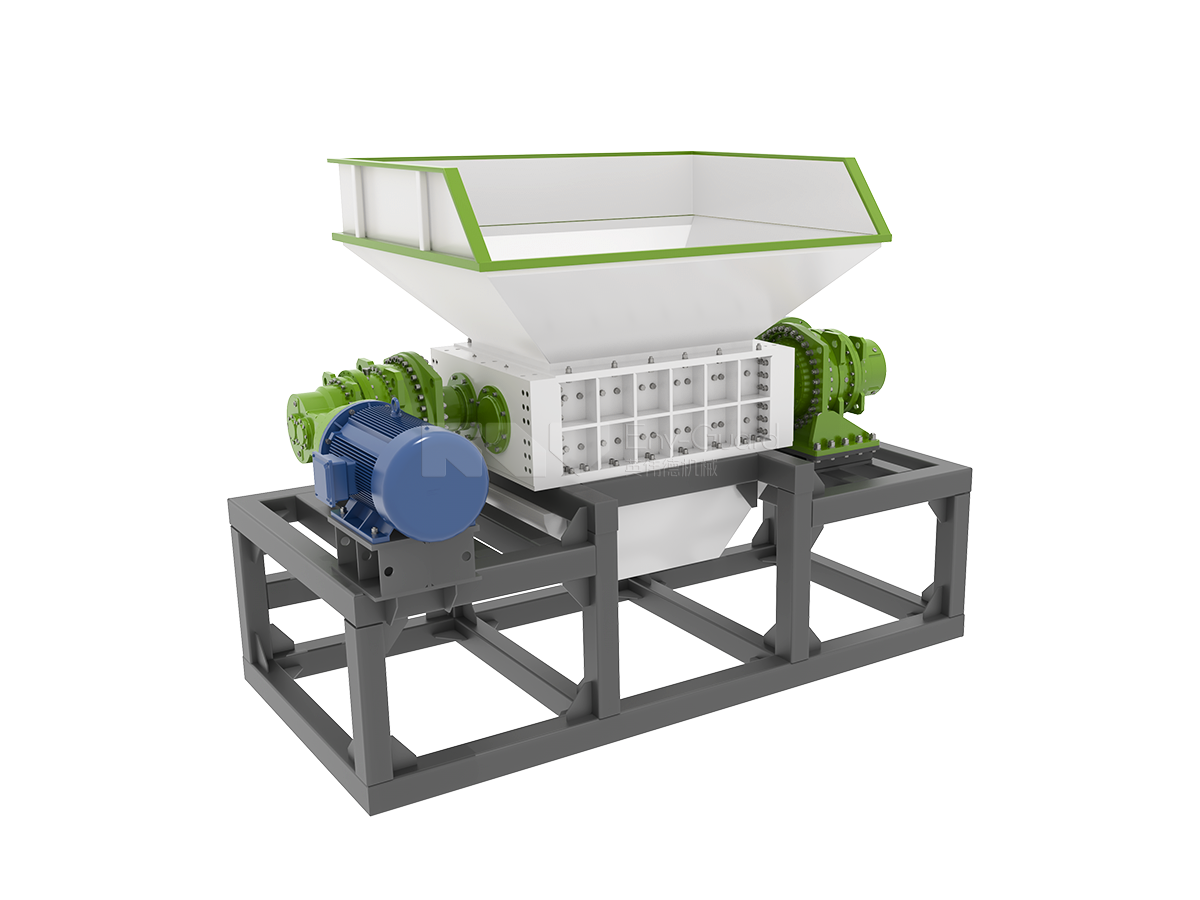

Double Shaft Shredder

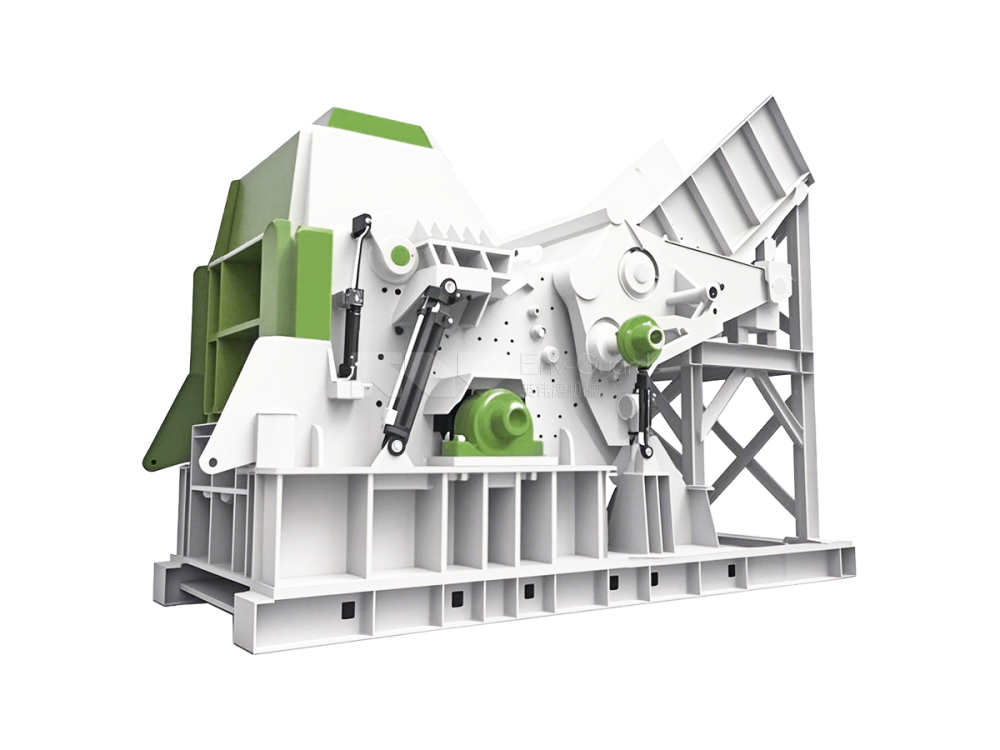

Horizontal Metal Shredder

Magnetic Separator

Vibrating Screen

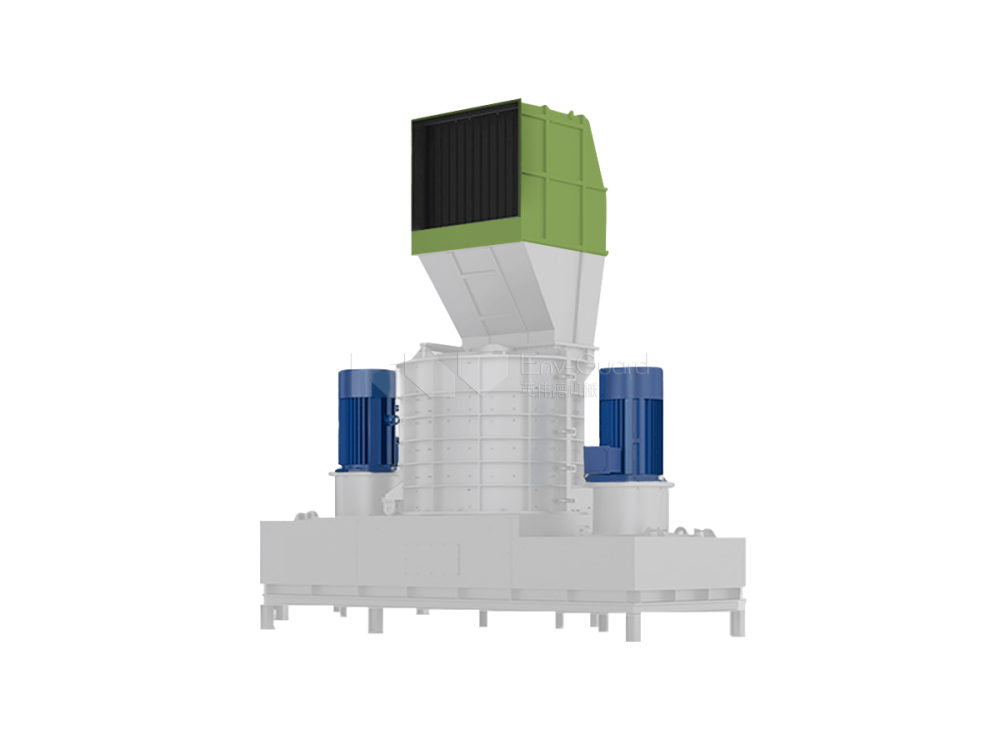

Vertical Metal Shredder

Finished Metal Particles

Competitive points

Env-Guard Metal Shredding Production Line Advantages

Consistent Particle Sizing

Adjustable shaft spacing/speed delivers uniform output, optimizing downstream separation and melting efficiency; reduces wear on furnaces/granulators.

Jam Protection

Special feeding systems adjust to material density and auto-reverse/auto-jam-clearance prevents overload, improving uptime by 20–25%.

Multi-Stage Sorting

Magnetic separators (ferrous recovery ≥98%), eddy current separators (non-ferrous purity ≥95%), and electrostatic separators (for fine particles) maximize material purity and yield.

High-Wear Blades

Alloy steel blades with HRC 58–62 hardness and reversible design, extending service life by 30–50% vs. standard blades; handles scrap with nails, bolts, or fasteners without jamming.

Latest updates

Global Cases

Solar Panel Recycling Plant in America

Lithium Battery Plant in Vietnam

Copper Wire Recycling Plant in India

What our client say

Happy With Customers & Clients

We are proud to announce that our waste recycling line has been successfully exported to over 100 countries and regions across the globe. This remarkable achievement underscores our commitment to environmental sustainability and our dedication to providing innovative waste management solutions worldwide.

We installed the medium-scale integrated line 8 months ago for mixed ferrous/non-ferrous scrap. The recovery rate hit 97% for copper—way higher than our old machine! The auto-jam clearance saves us 2+ hours of downtime weekly, and the dust control system passed local environmental checks with zero issues. Worth every penny.

Ali wakirwa

– Nigeria

Key Components

Metal Shredding Production Line Configuration

| Component Name | Key Function | Detailed Role in Process |

|---|---|---|

| Chain Conveyor | Heavy-Duty Feeding | Responsible for transporting heavy scrap loads (like car bodies or metal bales) evenly and steadily into the primary shredder. Designed to withstand high impact. |

| Double Shaft Shredder | Primary Shredding (Volume Reduction) | Uses low-speed, high-torque shearing blades to tear bulky items into rough strips (approx. 80mm). It breaks down the “tough” structure to prepare material for the secondary crusher. |

| Horizontal Metal Shredder (Hammer Mill) | Secondary Crushing & Densification | Uses high-speed hammers to impact the metal. It performs three critical tasks: 1. Paint Removal: Strips rust and paint from surfaces. 2. Nuggetizing: Pounds thin metal into dense, solid “nuggets” for higher melting efficiency. |

| Magnetic Separator | Ferrous Metal Recovery | Uses a powerful magnetic drum to pull Iron and Steel (Ferrous) materials out of the mixed stream. This separates clean steel nuggets from non-magnetic waste (aluminum, copper, plastic). |

| Eddy Current Separator | Non-Ferrous Metal Recovery | Uses a high-frequency magnetic field to create a repelling force. It “ejects” conductive Non-Ferrous metals (Aluminum, Copper) away from non-conductive trash (rubber, plastic). |

| Vertical Metal Crusher | Fine Grinding | further grinds the mixed material into uniform, small particles. This step ensures the material is the perfect size for density-based separation. |

| Specific Gravity Separator (Air Table) | Copper & Aluminum Separation | Since magnets cannot separate Copper from Aluminum, this unit uses airflow and vibration to separate them based on density. Heavier copper settles while lighter aluminum floats away. |

| Dust Removal System | Pollution Control | Captures dust, paint chips, and light debris generated during the high-speed crushing process, ensuring a safe working environment and environmental compliance. |

| PLC Control System | Automation & Safety | Provides centralized control with features like one-button start/stop, automatic overload protection, and fault diagnosis to prevent machine damage. |

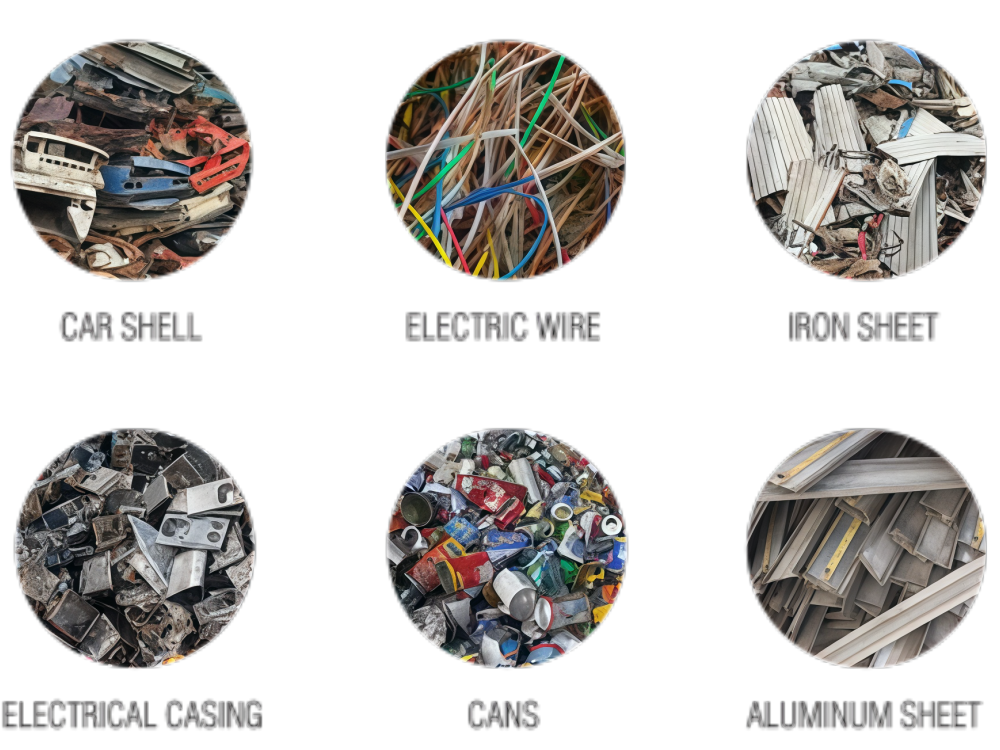

Wide application

What Is A Metal Shredding Production Line Used For?

A metal shredding production line is a specialized recycling system designed to process light-to-medium thickness, hollow or thin-walled scrap metal (after removing heavy solid components) into compact, uniform particles—ideal for melting and reuse in steel mills. Its core applications focus on the following materials:

1. Automotive Scrap

Processes waste car bodies (with engines, gearboxes, tires, and other heavy components pre-removed), converting bulky hulls into manageable metal fragments for recycling.

2. Tinplate & Thin Metal Products

Handles tinplate-based materials such as color steel tiles, iron barrels, and metal cans—reducing loose, irregularly shaped scrap into dense particles for efficient transport and smelting.

3. Household Appliance Scrap

Recycles the metal shells and frames of home appliances (e.g., refrigerators, washing machines, air conditioners) after stripping motors, compressors, shafts, and other solid internal parts.

4. Daily & Light Industrial Scrap Metal

Processes common metal waste like bicycles, truck fences, and similar household/light industrial metal items—simplifying the recycling of low-volume, diverse scrap.

5. Metal Containers & Drums

Shreds various thin-walled metal containers, including paint barrels, oil barrels, chemical barrels, and beverage cans—eliminating empty space and preparing them for material recovery.

6. General Light Scrap Steel

Accepts specific light scrap steel:

- Scrap blocks with a density < 0.6

- Steel plates with a thickness ≤ 6 mm

- Small steel sections, steel structural parts, and other thin-walled steel scrap

Work flow

How Does A Metal Shredder Plant Work?

A metal shredder plant processes scrap metal into reusable particles through 6 sequential, automated steps, tailored to handle hollow or thin-walled materials .

First, material feeding occurs: scrap like car bodies or appliance shells is loaded via chain or belt conveyors into the plant. These conveyors ensure continuous, stable feeding to avoid jams, keeping the production flow consistent from the start.

Next comes primary shredding: a single or double-shaft shredder first tears large, bulky scrap into smaller, manageable chunks—for example, breaking car bodies into 30–50cm pieces. This step alone reduces the material’s volume by 50–70%, making it easier to process downstream.

Then, secondary crushing takes place: hammer or vertical crushers refine the shredded chunks into uniform, dense particles (no larger than 10cm). This consistent sizing is ideal for the sorting and smelting stages that follow, as it ensures even processing of the material.

After crushing, material sorting begins. Magnetic separators extract ferrous metals like steel via magnetic attraction, while eddy current separators use electromagnetic repulsion to separate non-ferrous metals such as aluminum and copper. Specific gravity separators then remove non-metallic impurities (like plastic or paint residue) through vibration and screening, resulting in clean, sorted metal fractions.

Simultaneously, a dust control system—typically combining cyclone and baghouse filters—captures dust generated during shredding and crushing. This improves on-site air quality and ensures the plant complies with environmental emission standards.

Finally, material discharge and baling wrap up the process: sorted metal particles are conveyed to balers, which compress them into dense bales. These bales are easy to transport to steel mills or recycling facilities, completing the cycle of converting scrap into reusable feedstock.

The entire workflow is managed by an electronic control system, which enables one-button start/stop, real-time equipment monitoring, and safety features like overload protection—ensuring efficiency, safety, and minimal operational downtime.

Related products

Env-Guard Waste Recycling Machine For Sale

To complete your recycling suite, we also provide a variety of supplementary tools designed to optimize your recycling process and enhance efficiency.