Metal Hammer Mill Shredder

Output: Normally 6-8mm metal particles. Output size can be customized.

Large business choice

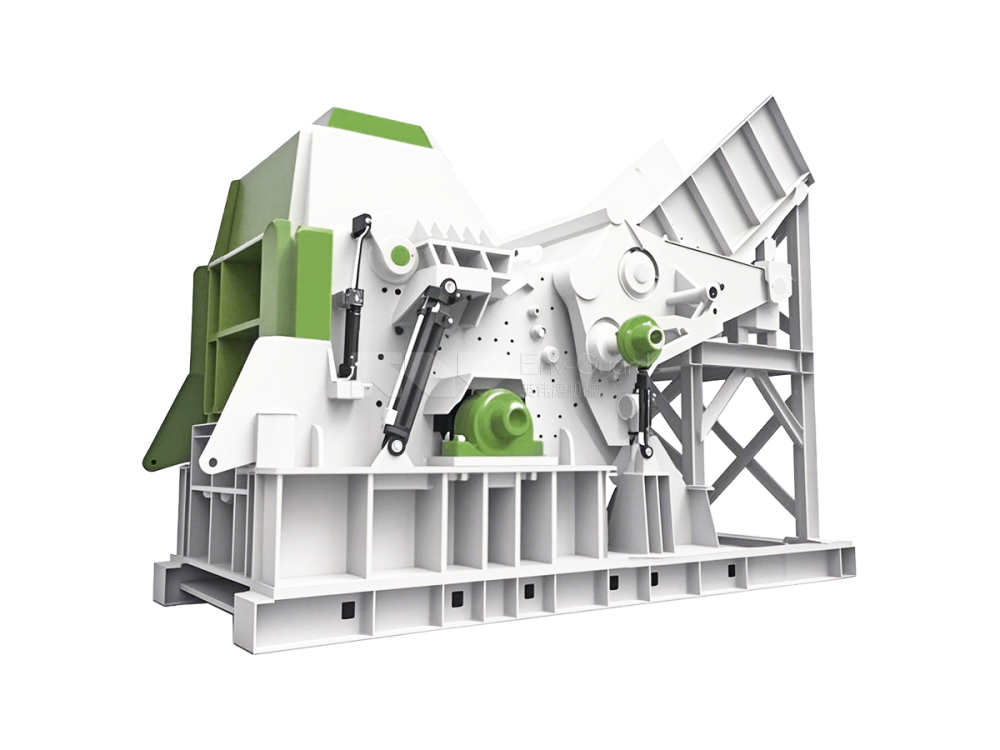

Horizontal Metal Crusher For Sale

Env-Guard horizontal metal crusher is designed to effectively crush a variety of metal materials such as scrap steel and scrap iron.

With high alloy blades ensuring durability, this crusher can process scrap metal plates, motors, steel scraps, and more. Its capacity ranges from 0.2 to 55 tons per hour, making it ideal for scrapyards, metal recycling plants, and automotive dismantling operations.

Input: crap iron, scrap steel, scrap iron drums, colored steel tiles, household appliances, scrap bicycles, thin iron sheets, raw aluminum aluminum alloys, and cans.

Feed Size: 1000-8000(mm)

For various business scale

Horizontal Metal Crusher Specification

| Model | Power(kw) | Capacity(kg/h) | Area covered(㎡) | Dimension(mm) |

| YWDJSP-W600 | 18.5-22 | 200-400 | 26 | 2650x1500x1850 |

| YWDJSP-W700 | 20-30 | 400-800 | 30 | 2800x1800x1950 |

| YWDJSP-W800 | 30-37 | 500-1000 | 35 | 2900x2300x2000 |

| YWDJSP-W900 | 37-45 | 600-1200 | 40 | 2900x2500x2100 |

| YWDJSP-W1000 | 75-110 | 1000-2000 | 50 | 3200x2600x2300 |

| YWDJSP-W1300 | 90-110 | 3000-5500 | 80 | 3800x3000x2800 |

Space-saving choice

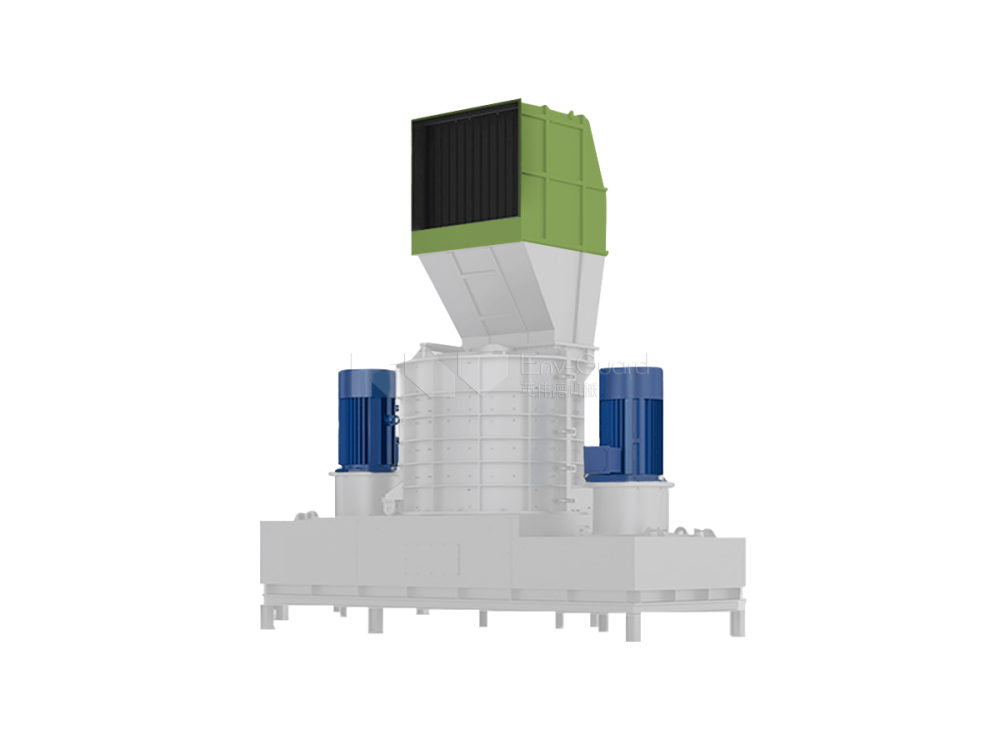

Vertical Metal Hammer Mill Shredder For Sale

Equipped with a high-speed hammer and impact plate, vertical metal hammer mill shredder pulverizes metal scraps into fine particles. This shredder plays a crucial role in metal recycling plants and industrial applications where the processing of bulky metal waste is essential.

By accepting a range of metal inputs, it produces consistently sized output ideal for smelting or further processing. Its compact design and high throughput make it a versatile solution for metal waste reduction.

Input: Car shells, refrigerator shells, computer cases, etc.

Feed Size: 100-5000(mm)

For various business scale

Vertical Metal Hammer Mill Shredder Specification

| Model | Capacity(kg/h) | Spindle Speed(rpm) | Number of Hammers(pcs) | Number of Hobs(pcs) |

| YWDJSP-L1000 | 800-1000 | 650 | 2 | 36 |

| YWDJSP-L1200 | 1500-2000 | 650 | 4 | 36 |

| YWDJSP-L1500 | 2000-3000 | 672 | 2 | 36 |

All-purpose choice

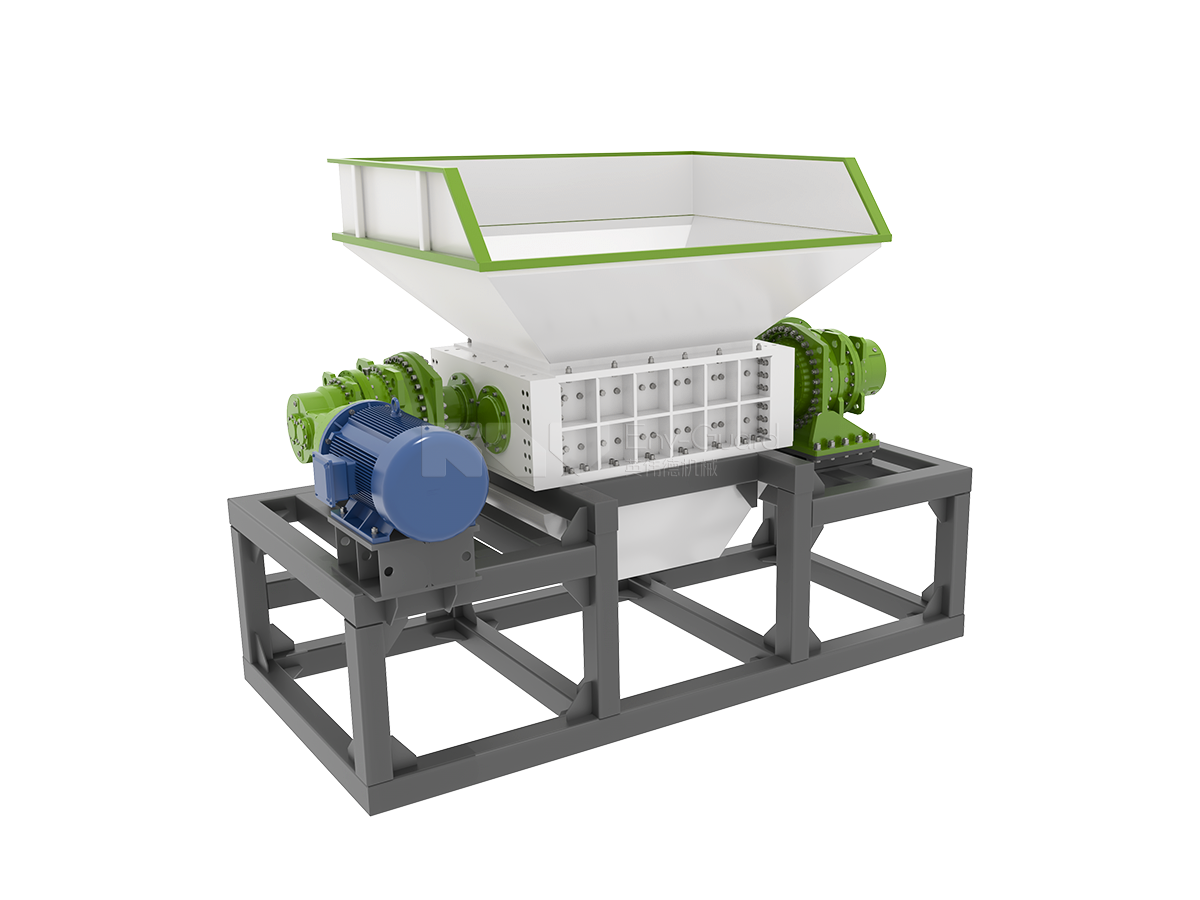

Scrap Metal Shredder For Sale

Whether dealing with bundled heavy-duty metal items or miscellaneous metal scraps, this shredder is engineered to efficiently disintegrate various types of metal materials. It serves as an indispensable tool in scrapyards, demolition sites, and metal recycling operations.

Noteworthy advantages of this shredder include its robust construction, high processing capacity, and adaptability to efficiently handle mixed metal scrap, contributing significantly to sustainable metal resource management.

Input: All kinds of iron, steel, copper, aluminum and other scrap metal products.

Feed Size: 1200-2500(mm)

For various business scale

Scrap Metal Shredder Specification

| Model | Powder(kw) | Capacity(t/h) | Blade Number | Input Opening Size(mm) | Weight(t) |

| YWD-FJS1000 | 30*2 | 5-10 | 34 | 1200*1000 | 5 |

| YWD-FJS1200 | 45*2 | 5-10 | 30 | 1500*1200 | 8 |

| YWD-FJS1500 | 55*2 | 8-18 | 38 | 2000*1500 | 13 |

| YWD-FJS1900 | 90*2 | 10-25 | 34 | 2500*2000 | 18 |

Competitive points

Env-Guard Hammer Mill Shredder Advantages

Less Metal Waste Reduction

Our metal crushers offer exceptional efficiency, reducing metal waste into manageable sizes swiftly and effectively, optimizing processing operations in scrapyards and metal recycling facilities.

High Quality & Long Lifespan

With high-quality construction and wear-resistant materials, Env-Guard metal crushers ensure long-lasting performance, minimizing downtime and enhancing overall productivity in metal processing.

Versatile Application

Our crushers cater to a wide range of metal materials, from steel to aluminum, from scrap cars to home appliances, providing versatile solutions for various industrial settings and metal recycling operations.

Ensures High & Quick Return

Our metal crushers optimize resource utilization, minimizing energy consumption and operational costs, offering a cost-effective solution for metal processing and recycling, maximizing returns on investment.

Latest updates

Global Cases

Metal Crusher Plant Operates in Philippines

Heavy Duty Metal Crusher Tested for Ghanaian Customer

Steel Wire Crusher Machine Tested for Malaysian Clients

What our client say

Happy With Customers & Clients

We are proud to announce that our waste recycling line has been successfully exported to over 100 countries and regions across the globe. This remarkable achievement underscores our commitment to environmental sustainability and our dedication to providing innovative waste management solutions worldwide.

Using the scrap metal crusher from Env-Guard Machinery has truly revolutionized our metal recycling operations. The machine’s robust design, high capacity, and versatility in processing various metal materials have significantly improved our efficiency. It’s a reliable asset that simplifies the recycling process, making it an essential tool for our scrap metal recycling facility.

Sohail anzar

– India

Wide application

What Is A Metal Shredder Used For?

Env-Guard metal shredders are designed to handle a wide range of metals and metal-containing products. Here are some of the materials that metal shredders can process:

Scrap steel: including auto parts, metal parts in home appliances (such as refrigerators, washing machines, etc.), steel containers (such as oil drums, gas cylinders), etc.

Non-ferrous metals: such as aluminium products (aluminium alloy doors and windows, aluminium foil, scrap aluminium alloys, etc.), copper products (scrap cables, copper pipes, etc.), lead products (lead battery shells, etc.)

Thin metals: such as iron sheets, cans, beer cans, metal scraps, electrical appliance shells, metal plates, etc.

Scrapped vehicles: including metal parts of scrap cars, motorcycles, bicycles and other vehicles

Construction waste: such as scrap steel bars, abandoned scaffolding, steel formwork, dilapidated metal doors and windows, building supports, etc.

The specific capabilities of a metal shredder can vary based on its design and the materials it’s intended to process. Some of our shredders are equipped with systems to remove non-metallic components, such as insulation from wiring or plastic parts from mixed metal products, allowing for more efficient recycling of the metal components. Contact our experts to discuss the machine details.

Work flow

How Does A Metal Shredder Plant Work?

A metal shredder operates by using a powerful motor to drive a shredding mechanism, which typically consists of a series of rotating blades or hammers that cut or crush the metal into smaller pieces. The basic operation of a metal shredder involves several key components and steps:

Feeding Mechanism: Metal waste is fed into the shredder through a conveyor belt or by manual loading, depending on the size of the shredder and the type of material being processed.

Shredding Chamber: The metal enters the shredding chamber where the actual shredding takes place. The chamber houses the shredding rotor equipped with cutting blades, hammers, or a combination of both.

Cutting Blades or Hammers: The rotor spins at high speeds, and the metal is impacted by the blades or hammers. In the case of rotary shear shredders, two counter-rotating shafts with interlocking cutting discs are used to slice the metal into smaller pieces. Hammermill shredders, on the other hand, use free-swinging hammers that pulverize the metal upon impact.

Screen or Grate: Below the rotor is a screen or grate with holes that determine the final size of the shredded material. Only pieces small enough to pass through the screen will exit the shredding chamber. Larger pieces remain in the chamber to be hit and cut again until they can pass through the screen.

Separation System: Some of our shredders have an integrated separation system that sorts the shredded metal by size or type using magnetic separation, eddy current separation, or other methods. This is especially important for mixed metal waste.

Discharge Conveyor: The shredded metal is then conveyed out of the shredder for further processing, storage, or transportation. This is typically done with a conveyor belt or by gravity, depending on the shredder’s design.

Control System: Our shredders are equipped with control systems that allow operators to adjust the speed of the rotor, the pressure applied to the material, and other parameters to optimize the shredding process for different types of metal waste.

Dust Collection and Noise Suppression: Shredding metal can produce a significant amount of dust and noise. Our shredders are equipped with dust collection systems to minimize airborne particles and noise suppression features to meet environmental and safety standards.

Cooling System: Due to the intense friction and impact forces involved in metal shredding, the equipment can generate a lot of heat. Shredders often have cooling systems to prevent overheating and to maintain operational efficiency.

Env-Guard metal shredders are robust and powerful machines designed to withstand the rigors of breaking down metal objects, which is a demanding process due to the toughness and variability of the materials being shredded. The specific design and features can vary depending on its intended use, the types of metals it is designed to process, and the required size of the output material.

Our shredder design

Metal Shredding Techniques

Env-Guard metal shredding machine involves a variety of techniques and technologies designed to break down metal materials into smaller, more manageable pieces for recycling and waste management. Here are some of the primary methods used in metal shredding:

Hammer Mills

Hammer mills is designed to use high-speed rotating hammers to crush and break down materials. The hammers are attached to a rotor that spins inside a metal housing; the metal enters the mill and is hit by the hammers, causing it to shatter into smaller pieces.

The size of the output can be controlled by the size of the perforations in the screen or grate that the material must pass through to exit the machine. Hammer mills are effective for a wide range of materials, including ferrous and non-ferrous metals.

Vertical and Horizontal Shaft Shredders

- Vertical Shaft Shredders: These shredders have a vertical rotor with hammers or cutters. They are often used for size reduction of light scrap, such as aluminum or small electronic parts. The gravity assists in the downward flow of materials through the shredder.

- Horizontal Shaft Shredders: These shredders have a horizontal rotor and are more common in the industry. They can handle a wider variety of materials, including bulky ferrous metals. Horizontal shaft shredders can be further categorized into single-shaft, dual-shaft, and four-shaft shredders, depending on the number of rotors present.

Granulators

Granulators are high-speed, rotary cutters that finely chop the metal into granules. Unlike hammer mills, granulators are used for finer size reduction and are particularly effective for cables and wiring, small metal parts, and other non-ferrous materials. They work by cutting the material with knives on a high-speed spinning rotor against a fixed bed knife.

Scrap Metal Shredders

Scrap metal shredders are specifically designed to shred large volumes of metal scrap. They are robust and capable of processing a variety of metal products, including car bodies, white goods, and other structural metals.

Each metal shredding technique has its own set of advantages and is chosen based on the specific requirements of the material to be processed, the desired size of the output, and the subsequent processing steps. The choice of shredding technology also depends on factors such as energy consumption, maintenance requirements, and operational costs.

Market analysis

Is Metal Recycling Business Profitable?

Growing Demand for Recycling: As global awareness of environmental issues rises, the demand for metal recycling is increasing. Governments and industries are focusing on sustainable practices, creating a robust market for recycled metals.

Resource Scarcity: With the depletion of raw materials and rising extraction costs, recycling metals offers a cost-effective and sustainable solution. Metal shredders help process scrap efficiently, making recycled materials readily available for manufacturing.

High Profit Margins: Scrap metal prices can be lucrative, and with efficient processing, the margin between the cost of shredding and the selling price of the recycled metals can be significant.

Diverse Market Applications: Recycled metals are used in various industries, including automotive, construction, and electronics. Investing in metal shredding positions a business to cater to various sectors, expanding potential revenue streams.

Technological Advancements: Innovations in metal shredding technology enhance operational efficiency, safety, and throughput. Investing in modern equipment can lead to lower operational costs and increased productivity.

Regulatory Support: Many regions have regulations encouraging recycling and reducing landfill waste. This supportive legislative environment can create a favorable business climate for metal shredding operations.

Global Trade Opportunities: Scrap metal is a tradable commodity on a global scale. Establishing a foothold in this market can allow businesses to tap into international supply chains.

Long-Term Scalability: As industries evolve, the need for efficient metal processing will likely grow. This creates opportunities for business expansion through increased capacity or diversification into related services.

In summary, the metal crusher and shredder business not only meets a critical need in today’s economy but also offers significant financial and operational advantages, making it a compelling investment opportunity.

Related products

Env-Guard Waste Recycling Machine For Sale

To complete your recycling suite, we also provide a variety of supplementary tools designed to optimize your recycling process and enhance efficiency.